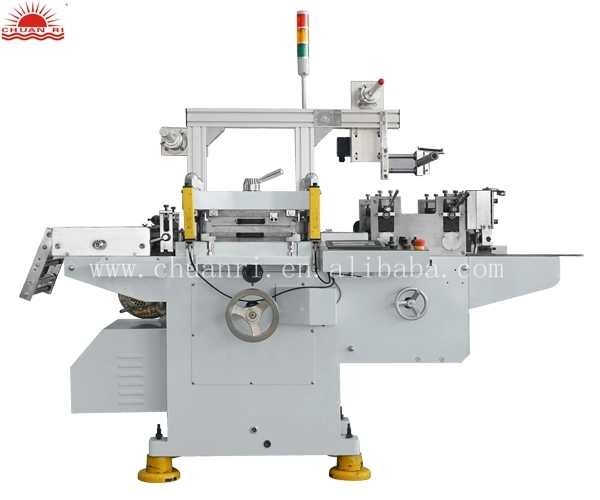

High Speed Flat Bed Half Cut Die Cutting Machine For Adhesive Tape/Label/PET Film

Function And Characteristic

1. The frame of machine is iron casting , which makes sure mahcine is strong enough. We have our own advanced CNC center, which makers sure the production of the machine with high precision. Which make sure it stable , long lifetime and heavy die cut pressure.

2. Closed oil is used for avoid rusty of the gear box. Most important thing is that it can reduce the friction. Meantime, we can get a quite working surrounding.

3. Three working mode : single die cut, continuous die cut, jogging . Easier to operate.

4.Automatic lubrication system, it can offer oil together.

5. It is helpful to improve the die cut speed. 260 cuts/min . Such speeds is 50% faster than traditional die cutting machine.

6. Servo trasmission is used of instead of tradition clutch structure to control the sheet cutter. It is helpful to get more accurate cut under faster die cut speed. And continuous cutting function is helpful to get lifetime of the cutter.

Application

This machine is suitable for convert adhesive label, protective film, electronic shielding materials, pvc, film, malay, copper foil, aluminum foil, double adhesive, foam etc. And also can used in reflector plate, diffuser, buffer plate,silicon tape etc for LCD.

Main parameters

Can add:

1.Hot Foil Stamping

2.Sheet Cutter

3.Laminator

4.Punching

5.Those according to custom require

Standard machine--Unwind + die cutting machine

Add Conveyor Belt

After die cutting, the product will attach the bottom film and collect

Add Punching Function

Hot Foil Stamping

Company information

We are manufacturer and specialized on die cutting machine, slitting machine, laminating machine adn roll to sheet cutting machine, those machine all suitable for roll material, we can make them from roll to roll or from roll to sheet.

For the location of our company: No309 Kangzhuang Rd. Zhoushi Town, Kunshan City, 215314, Jiangsu Province, China.

Near Shanghai, less than 20 minutes by train from Shanghai staion or Hongqiao station to Kunshan shan south station ( Kunshan city belong to Suzhou city ).

Welcome to visit our company.

Packing

Delivery in China Market

Contact us

Function And Characteristic

1. The frame of machine is iron casting , which makes sure mahcine is strong enough. We have our own advanced CNC center, which makers sure the production of the machine with high precision. Which make sure it stable , long lifetime and heavy die cut pressure.

2. Closed oil is used for avoid rusty of the gear box. Most important thing is that it can reduce the friction. Meantime, we can get a quite working surrounding.

3. Three working mode : single die cut, continuous die cut, jogging . Easier to operate.

4.Automatic lubrication system, it can offer oil together.

5. It is helpful to improve the die cut speed. 260 cuts/min . Such speeds is 50% faster than traditional die cutting machine.

6. Servo trasmission is used of instead of tradition clutch structure to control the sheet cutter. It is helpful to get more accurate cut under faster die cut speed. And continuous cutting function is helpful to get lifetime of the cutter.

Application

This machine is suitable for convert adhesive label, protective film, electronic shielding materials, pvc, film, malay, copper foil, aluminum foil, double adhesive, foam etc. And also can used in reflector plate, diffuser, buffer plate,silicon tape etc for LCD.

Main parameters

| Model | MQ-S-320 |

| Max feeding width | 320mm |

| Die cut speed | ≤260cuts/min |

| Precision | ±0.10mm |

| Cutting area | 300*300mm |

| Main power | 3kw |

| Voltage | 380v |

| Weight | 1350kg |

| Size | L*2350*W1250*H1600mm |

| Total power | 6kw |

Can add:

1.Hot Foil Stamping

2.Sheet Cutter

3.Laminator

4.Punching

5.Those according to custom require

Standard machine--Unwind + die cutting machine

Add Conveyor Belt

After die cutting, the product will attach the bottom film and collect

Add Punching Function

Hot Foil Stamping

Company information

We are manufacturer and specialized on die cutting machine, slitting machine, laminating machine adn roll to sheet cutting machine, those machine all suitable for roll material, we can make them from roll to roll or from roll to sheet.

For the location of our company: No309 Kangzhuang Rd. Zhoushi Town, Kunshan City, 215314, Jiangsu Province, China.

Near Shanghai, less than 20 minutes by train from Shanghai staion or Hongqiao station to Kunshan shan south station ( Kunshan city belong to Suzhou city ).

Welcome to visit our company.

Packing

| MOQ | 1 Set |

| Packing Detail | packing(inner): Stretch film |

| Packing(outside):Wooden frame | |

| Delivery Time | 20-40 days after get your deposit and confirmed all the Details |

| Delivery Port | Shanghai |

| Terms Of Payment | L/C T/T Western Union |

| Guarantee | The whole machine is guaranteed for one year. |

Delivery in China Market

Contact us